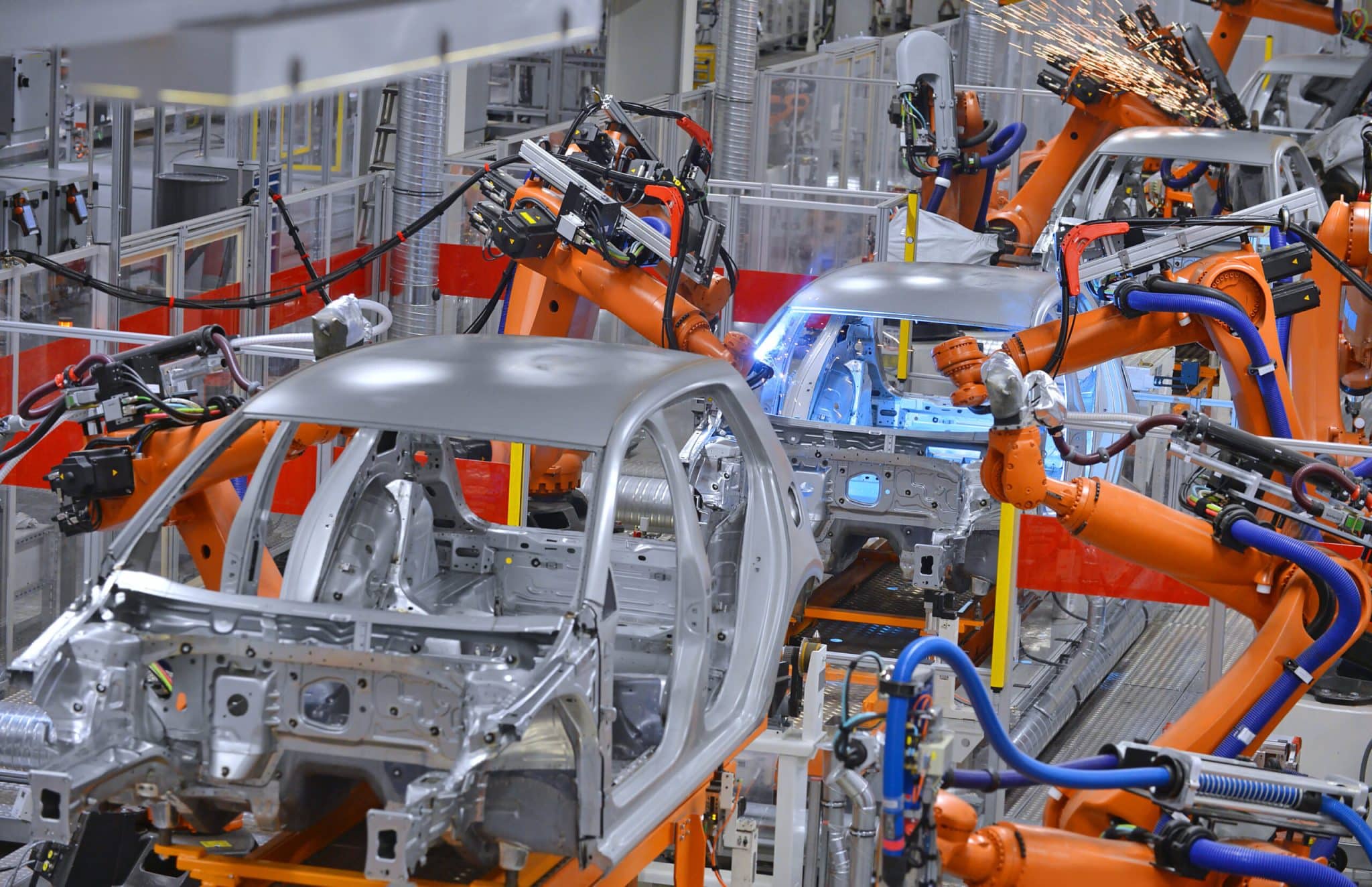

Advanced, automated assembly machines

If you are looking for a way to improve on labor costs, product reliability, and consistency within your manufacturing business, then it is time to consider designing custom assembly machines with Commonwealth Tool & Machine in Georgetown, Kentucky. We create custom automated equipment for multiple applications such as weld cells, compression machines, end effectors, gravity conveyers, CDLR conveyers, and more! These advanced machines are compatible with electric motors, pneumatics, hydraulics, servos, hand clamps, or any combination of multiple devices. Let these smart systems revitalize the way that you engineer and fabricate your products!

Superior mechanized production

Computers, mechanics, and electronics all intersect to create an assembly machine that assembles and manufactures whatever you need. At Commonwealth Tool & Machine, we employ highly skilled, well trained, and knowledgeable mechatronics engineers to orientate your new assembly machines to their advanced automation duties. Our programmers run specialized high tech computer programs that control the assembly automation. With the knowledgable assistance of our assembly machine design team, you will decide if you will require humans to interact with the machines. In some cases, a machine operator is required for “feeding” parts to the assembly machine, though this is not always necessary as assembly machines can be fully automated.

Innovative assembly machine technologies

Our engineers guide Commonwealth Tool & Machine’s automated custom assembly machines through the construction processes with well written software programs that we create especially for you. These automated guided systems build larger objects like automobiles or even tiny, microscopic products like computer motherboards. Commonwealth Tool & Machine builds any type of computerized manufacturing machine based on your specific instructions including:

- In-line machines

- Dial Index machines

- Continuous motion machines

- Floating work platform machines

- Collaborative robots

- Six axis, Delta, and SCARA robots

Gain from custom assembly machines with:

- Consistency – Automated assembly machines are more capable of performing repetitive tasks with fewer mistakes than a human employee. Avoid backups and shutdowns on the assembly floor and get fool proof results and consistent products.

- Value and Profit – Assembly machines create more impressive profit margins because of their ability to cut labor costs and produce greater output while performing with higher standards, which increases your overall profitability.

- Space – You don’t need a sprawling warehouse when you utilize assembly machines, because a lot of products can be manufactured and packaged within a smaller footprint.

- Ability - Assembling miniscule objects that otherwise would be potentially impossible for human workers to assemble is easy for an assembly machine and is very efficient for mass production.

- Precision – With precise programming from Commonwealth Tool & Machine, you never have to worry about inconsistencies. Make certain that every item you manufacture is created equal.