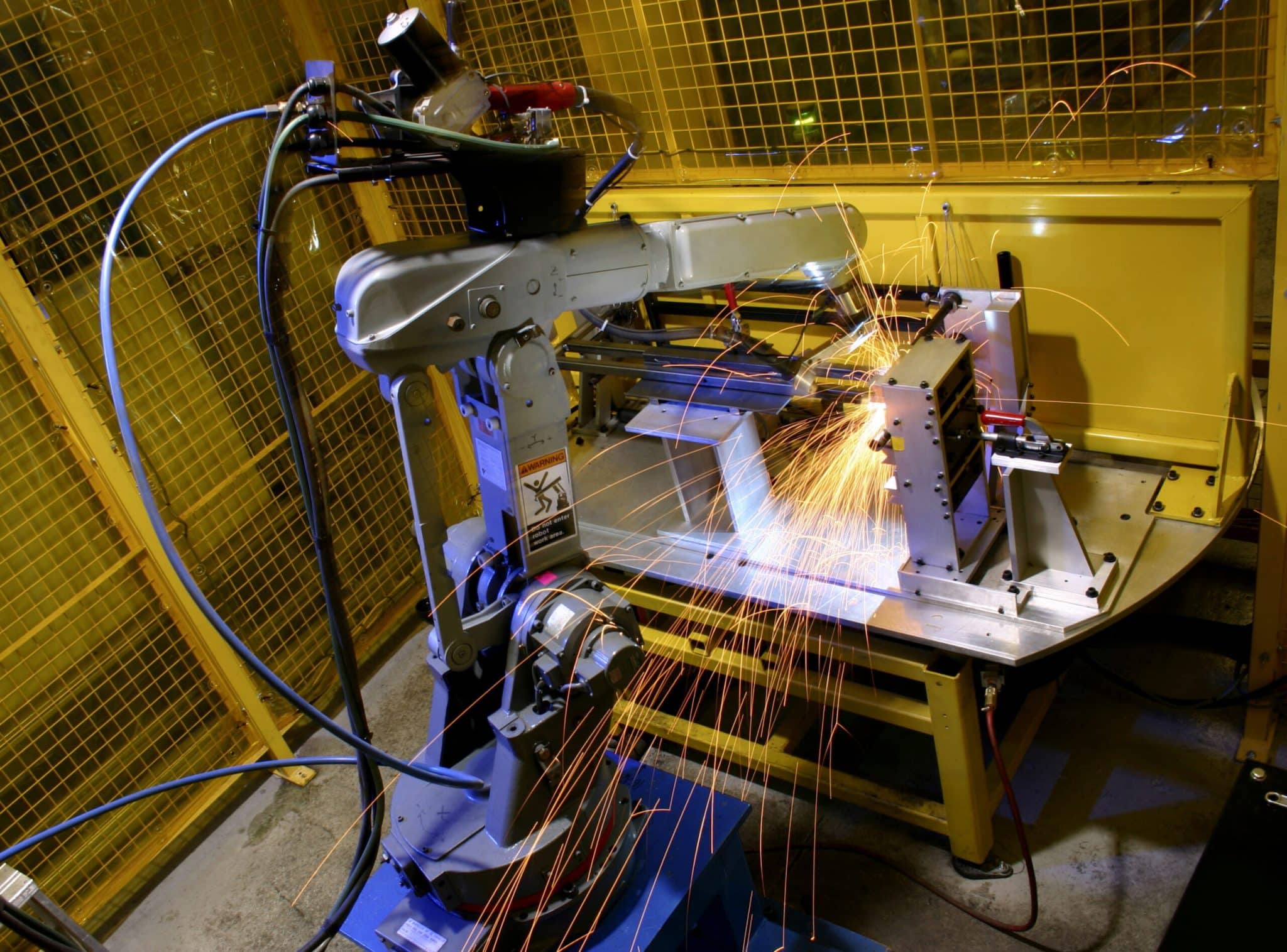

Weld integrity you can depend on

Are you interested in automating your welding workforce? Press welding machines, also known as resistance welding machines, are perfect for projection welding and some spot-welding processes. Unquestionably, press welding machines have more than two times the production capacity than that of a human being. Additionally, this welding process has been in existence for over 2,000 years. These methods are time tested and true. The final products are always reliable though the technology is much different now and vastly improved. Let Commonwealth Tool & Machine create your custom designed press welding machines in Georgetown., Kentucky!

The workhorse of welding

Resistance and press welding machines use resistance pressure from a specialized clamp and electrical currents to perform the welding process. This method places the greatest amount of surface area pressure and contact between the two pieces of metal as possible. Multiple electrode nodules guide sturdy and stable weld arms through the process. A strong bond is made when the metal bears heat and pressure from the electrical current flow via conductors. This automated use of energy is a steadfast way to ramp up your manufacturing productivity when the competition heats up.

Don’t let the pressure stall your production

Commonwealth Tool & Machine builds customized press welders with excellent resistance. We have a team of highly trained and knowledgeable welding design engineers ready to bring you the automated press welding designs that you have been dreaming of at our state-of-the-art facility in Georgetown, Kentucky. Commonwealth Tool & Machine creates custom press and resistance welding machines with programmable systems and controls per your specifications. Each custom weld machine that we build will go through our mechanical and electrical design processes, and travel through our shop to be built and then tested at our facility. Our reliable operations will leave you feeling confident in our manufacturing capabilities to create complex and programmable resistance and press welding machines.

Automated for efficiency and safety

Custom automated resistance and press welders are more efficient and give nearly perfect results, every time. Here are just a few ways how:

- Reliability. You will always count on automated press welding machines because of their inherent control capabilities.

- Superior weld quality. Press welding machines will repeat the same motions again and again with mechanical supervision.

- Less waste. There are fewer mistakes made so there are less misspent fragments and rejects, and less money is spent on materials.

- Better management. It is easy to run and direct the welding action.

- High quality craftsmanship. Automated machines do not get tired or get “shaky hands” like humans do.

- Cost effective. You just need metals and electric currents in order to get tot work. Our automated welders produce far more in a shorter period of time.

- Safety. Keep your employees out of harm’s way and protect them from potentially dangerous flash burns and heat.