Custom inspection solutions

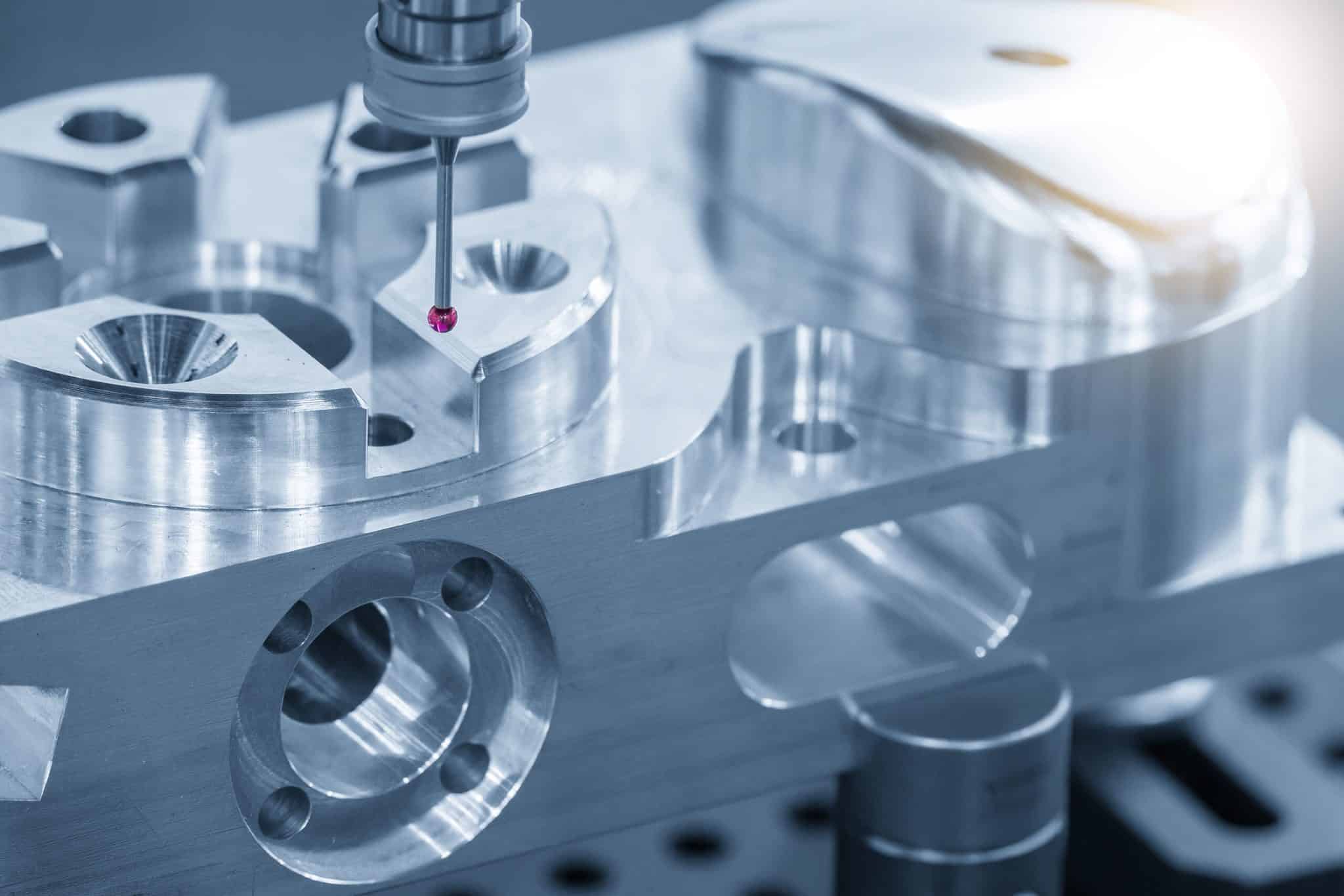

Commonwealth Tool & Machine specializes in manufacturing a wide variety of custom inspection gauges for various applications in Georgetown, Kentucky. Precision gauge measurement tools verify important safety and production attributes in an assortment of industries. Inspection gauges are customized for particular applications and made specifically to check parts and assembly details to ensure they are aligned accurately. They are important measuring devices in the fields of design engineering and the automotive industry. Inspection gauges measure the size of the object and also specify if the dimensions of the object are within the defined safety tolerance range standards. It is imperative that inspection gauges are built to exact specifications to serve their purpose satisfactorily. Commonwealth Tool and Machine also offers exceptional CMM services and we guarantee that our inspection gauges are second to none.

High accuracy inspection gauges

Commonwealth Tool & Machine manufactures small, simple gauges as well as large, complex, muti-axis gauges that meet customer specifications for all applications. We are here for you whether you require a simple gauge for tooling purposes, gauges for heavy or light duty vehicles, or gauges for part production, including assemblies. Commonwealth Tool & Machine uses the latest machine tool technology to manufacture our inspection gauges. This technology includes simultaneous 5-axis machining that enables us to machine complex shapes and undercuts with high accuracy. The materials that we use include high density resin, aluminum, hardened steel, or any customer specified material. Additionally, we offer combinations of specialty materials.

Efficient inspection control

Manufacturers monitor the quality of their components during the entire production process. For example, even though the future looks bright for electric vehicle growth, internal combustion engines remain at the core of automotive applications. The main goal is to achieve highly efficient fuel economy for these applications, as well as low emissions. Some automotive manufacturers are almost ready to provide new versions of internal combustion engines. They will need to achieve a lower percentage of emissions compared to the vehicles in the current market. The quality of the manufacturing process is based on the quality of the measurements of the specific features. Specifically, the main components of the injection industry must be accurately controlled.

Designed to your specifications

We produce high quality gauges with extreme precision capabilities at Commonwealth Tool & Machine. We confirm the quality of our work with a multi-stage inspection process. Our team verifies all measurements in a temperature-controlled environment to ensure there is no inaccuracy due to thermal expansion. At Commonwealth Tool & Machine we utilize a variety of quality assurance methods. We will finish your components to your exact specifications, on your schedule. Size, shape, and complexity are of no concern. Our team has decades of experience and the knowledge to design custom tooling and fixturing to ensure your inspection gauges are produced to your exact specifications.