Waterjet cutting systems for any endeavor

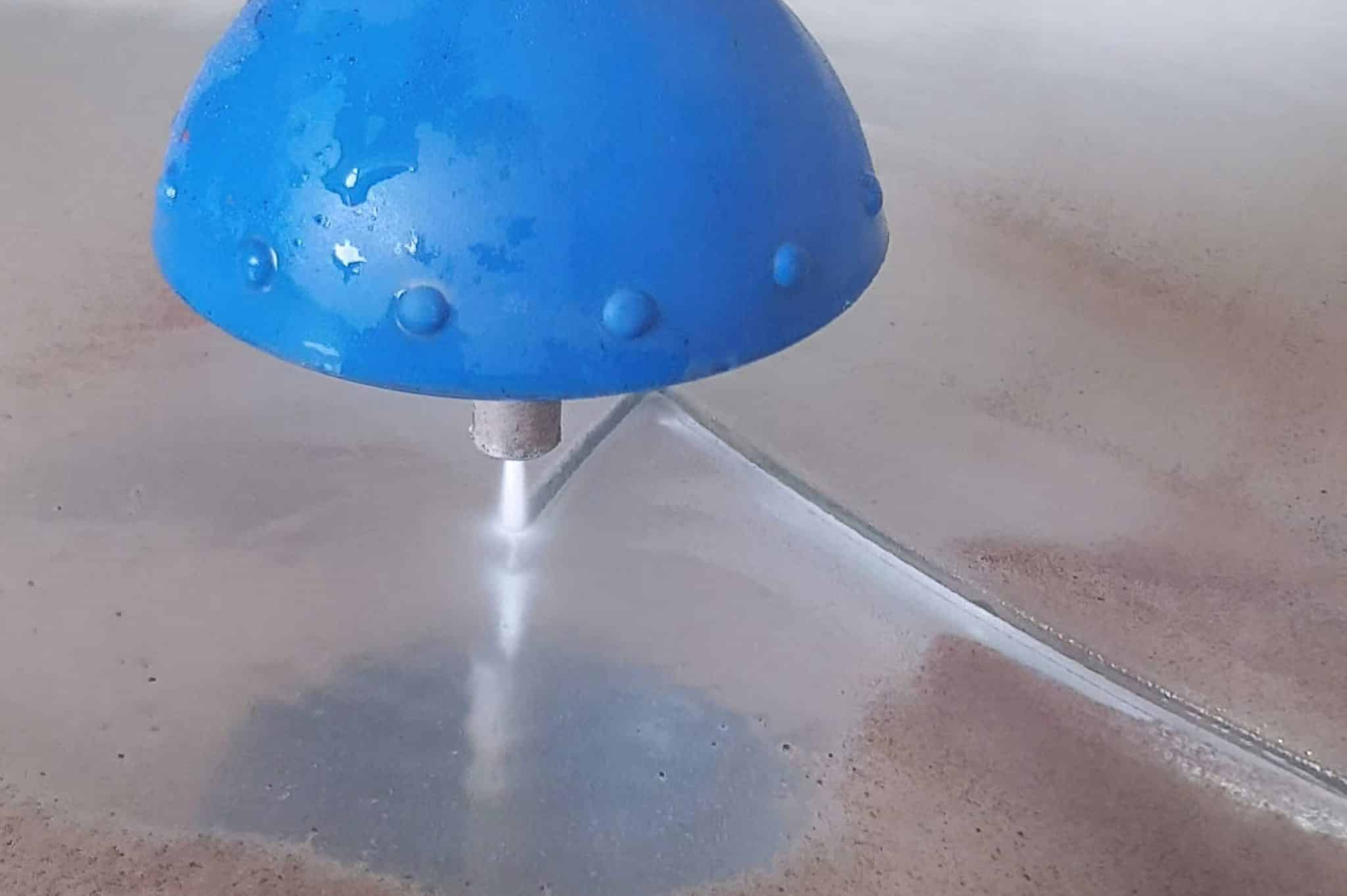

Here at our facility in Georgetown, KY you will find state-of-the-art waterjet cutting systems: a high powered, high precision, pressurized sonic jet stream of water, utilized for seamless custom cutting to your specifications. Waterjet cuts are made by sonic force that generally reach ultra-rapid speeds up to 2500 mph. Once the water erodes the product material, your creation is ready for design fabrication. In using this especially precise, detailed, and dependable technology, you can set big expectations for the growth of your industry. Waterjet cutting systems can can turn any material you can imagine into any concept that you can dream of. Surely almost any project is conceivable with this functional and effective technology, regardless of what you need to manufacture.

Cut out the competition

Come and see what Commonwealth Tool & Machine can accomplish! We will cut, shape, and design a product to your unique blueprint details. Our versatile waterjet cutting systems can create up to 5 dimensional cuts, specializing in complex patterns with smooth edges for efficient flow integration to your final product. Comparatively, nothing can exceed the precision that waterjet cutting provides. For example, waterjet cutting systems can provide functional and multi-faceted uses for materials such as:

- Glass

- Granite

- Wood

- Paper

- Plastics

- Composites

- Tile

- Ceramics

- Porcelain

- Fiberglass

- Aluminum

- Natural stone

- Rubber

- Concrete

- Stainless steel

Applicable anywhere your imagination can take you

With our ability to waterjet cut practically anything into fruition, we are certain that Commonwealth Tool & Machine will prove to be your best bet for production of any type of article needed for any type of manufacturing endeavor, including but not limited to:

- Electronics

- Auto industry

- Tool fabrication

- Machining shops

- Medical tools

- Architecture projects

- Aerospace

- Aquatic vessels

- Furniture construction

- General manufacturing

Profitable precision with waterjet cutting systems

With no need for any additional finishing of the final pieces, this cost-effective manufacturing technology will permit you to rapidly produce your completed parts. Waterjet cutting is also advantageous to your company’s financial well-being because Commonwealth Tool & Machine can provide exceptional detail in product integration. This method of production is also superior for prototype building and testing as the finished pieces can be completed in a timely fashion, priming your business for more seamless and reliable launch expectations. Waterjet cutting systems also increase your business’s profitability by decreasing the need for excess manual labor as well as reducing the cost of raw materials needed, as the cutting system is so precise that it does not create a lot of waste bi-product. From an environmental standpoint, no toxic or harsh chemicals are used, and for the purpose of waste reduction this also keeps excess materials out of the landfill.