Superior weld reliability

Commonwealth Tool & Machine’s custom welding inspection gauges inspect your final fabrications and ensure that your welding processes are completed flawlessly. Welding inspection gauges are perfect for checking weld alignment, checking pre-weld dimensions, verifying post-weld dimensions, and checking porosity of welds. Measurement and inspection of welded joints is an important step in quality control and reliability of welded constructions. External inspection allows you to detect defects such as undercuts, uncertified craters, facing surface cracks, lack of fusion, flows, and more. If you are looking for weld inspection gauges that you cannot find anywhere else, Commonwealth Tool & Machine in Georgetown, Kentucky is here to engineer the tools that you need.

Quality welding inspection gauges

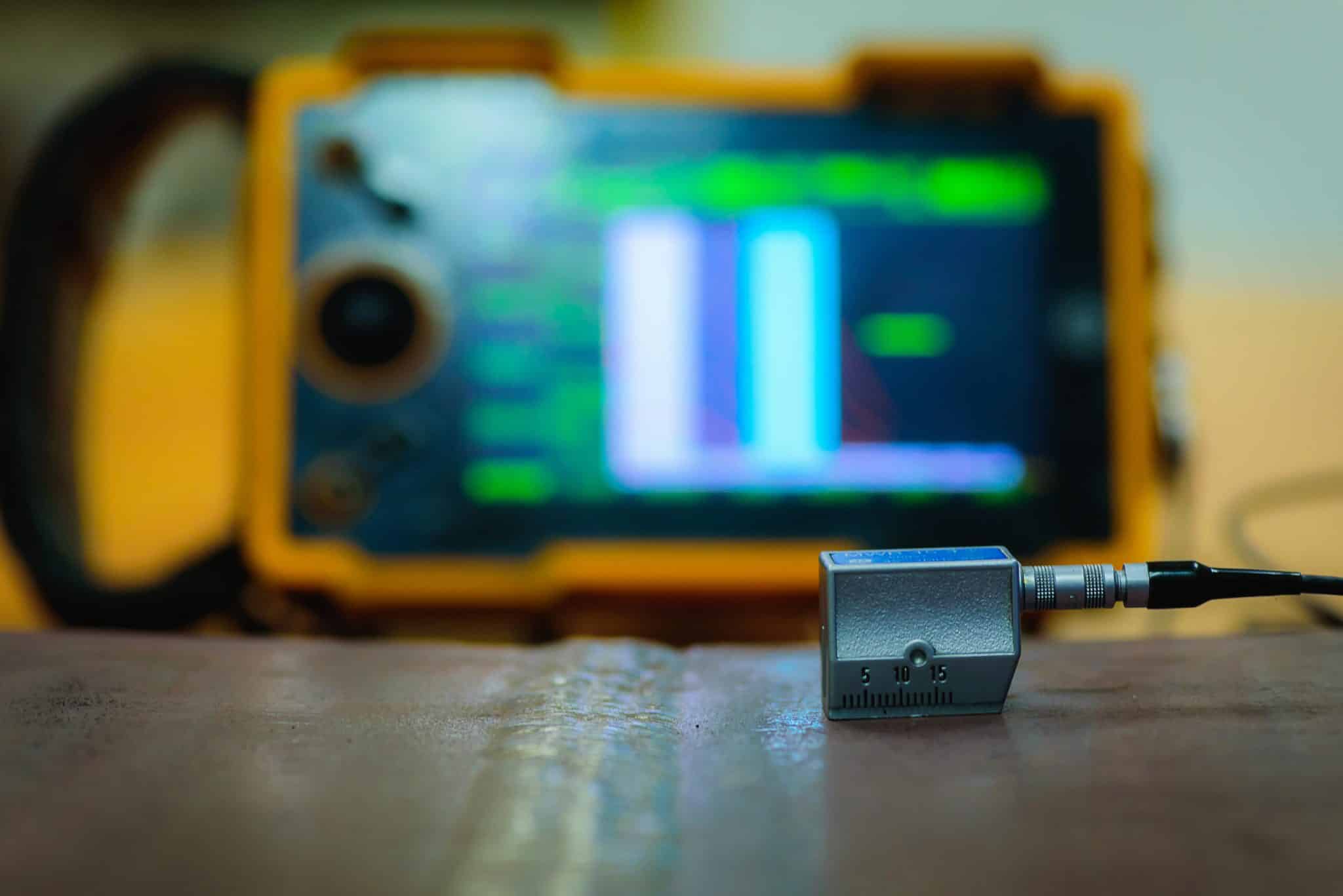

While the visual inspection of welds is important, ultrasonic flaw detectors are the industry standard for weld testing. Ultrasonic flaw detectors test welds using sound waves to determine the positioning and thickness of welds. They also identify cracks, voids, and other discontinuities in welds that might lead to material component failure. Weld quality testing uses tools such as weld inspection gauges and ensures the quality and strength of welds to prevent catastrophic failure of defective welds. Quality inspection is also done purely as an inspection operation. Previously welded assemblies are analyzed for quality after arrival from subcontractors or before other assembly stages. These inspection systems also analyze weld quality in locations where human access and assessment is difficult, like in tightly enclosed spaces.

Accurate results, every time

A weld force gauge accurately measures the actual weld force at the seam. It is important to calibrate these instruments because a weld force that is too low or too high eventually causes problems such as cracking, indentation, expulsion, and low weld strength. Commonwealth Tool & Machine creates custom welding inspection gauges of the highest quality, suitable for a variety of uses. They allow you to measure welds quickly and easily, and achieve accurate results every time. Custom welding inspection gauges from Commonwealth Tool & Machine are perfect for measuring alignment, checking dimensions before welding, verifying weld dimensions, and confirming the porosity of welds. Commonwealth Tool & Machine designs and engineers custom gauges that are:

- Single-purpose

- Multi-purpose

- Dial

- Digital

- Hi-Lo

- Fillet

- Mini-sub

- Bridge cam

Inspection precision

Commonwealth Tool & Machine offers automated weld inspection capabilities as standalone systems, as well as integrated larger welding and manufacturing constructs. Automated weld analyzing systems integrate into robotic weld cells to track weld performance in real time. It is also possible to complete the inspection process as its own stage after the weld is complete. Automated weld inspection systems check the weld geometry, as well as the weld length, shape, volume, and weld alignment. Additionally, these systems detect defects in the weld that may also occur. These welding inspection systems frequently utilize the same robot from the welding process. This reduces upfront expenses and programming times. Automation helps manufacturers increase productivity, reduce the cost of labor, and improve the return on your investment. Commonwealth Tool & Machine revolutionizes the way our clients optimize their production with our advancements in precision welding inspection gauges.